Some Ideas on Plastic Injection Molding You Should Know

Table of ContentsExcitement About Plastic Injection MoldingThe 15-Second Trick For Plastic Injection MoldingThe Main Principles Of Plastic Injection Molding The 2-Minute Rule for Plastic Injection Molding

If you intend to check out additionally, the guide covers sorts of mould tools, along with unique completing processes such as colours & plating. Words that are underlined can be found in the glossary in the appendix ... Component I: Moulding: The Fundamentals The Advantages of Shot Moulding Plastic injection moulding is a really precise procedure that provides numerous advantages over other plastic handling techniques.

Accuracy is excellent for extremely detailed parts. You can hold this moulding in the palm of your hand and also it has bosses, ribs, metal inserts, side cores as well as holes, made with a gliding shut off function in the mould tool.

Making use of a UK moulder with existing ties to China can remove the threat and also still result in cost-saving ... Cavity - The part of a shot mould device that gives the plastic item its form, that does the real moulding of the plastic. See mould device phase on pages 5 and also 6 for all terms connected with the mould device Cycle time - The time it takes for a mould cycle to be completed, i.

from material feed Product melting; material injectionProduct shot time cooling down ejection as well as the re-closing of the mould tool ready device all set next cycleFollowing Draft angles - The wall surfaces of a moulded part must be a little tapered in the direction in which the component is expelled from the mould tool, to allow the component to be ejected easily (plastic injection molding).

Ejector stroke - The pressing out of ejector pins to eject the moulded component from the mould device. Ejector stroke rate, length as well as timing needs to be meticulously controlled to avoid damages to the ejectors and also mould device, yet at the same time make the moulding cycle as short as feasible.

Some Known Incorrect Statements About Plastic Injection Molding

Overlocking - When a mould device has actually been set into a moulding maker improperly, creating the device to shut as well hard and so destructive the mould device Component repeatability - The capability to develop the same plastic components time after time Distance - Completely straight edges are impossible to eject from the mould tool.

Ribs - When a plastic component has slim wall surfaces, ribs are added to the design to make the thin walls more powerful Side cores - Side activity which creates a function on a moulded component, at an opposing angle to the typical opening direction of the mould device. The side core needs to be able to withdraw as the plastic component can not be ejected or else.

Wall surfaces - The sides of a moulded component The message on this page is a sample from our complete White Paper 'Shot Moulding for Purchasers'.

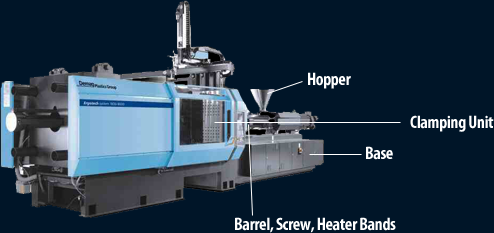

Shot moulding is commonly made use my response of for producing a range of parts, from the tiniest elements to entire body panels of cars. Advancements in 3D printing modern technology, utilizing photopolymers that do not thaw during the shot moulding of some lower-temperature thermoplastics, can be used for some straightforward injection moulds. Injection moulding makes use of a special-purpose device that has three parts: the shot device, the mould as well as the clamp.

The Ultimate Guide To Plastic Injection Molding

In several cavity moulds, each dental caries can be identical and also create the exact same components or can be distinct and also form several different geometries throughout a solitary cycle.

The screw provides the raw product ahead, mixes and also homogenises the thermal and also thick distributions of the polymer, and lowers the required home heating time by mechanically shearing the product and also adding a considerable quantity of frictional home heating to the polymer. The product feeds forward with a check valve as well as accumulates at the front of the screw into a quantity called a shot. When enough product has actually collected, the product is forced at high pressure and also speed into the component developing tooth cavity. The precise quantity of shrinking is a function of the resin being used, as well as can be reasonably predictable. To stop spikes in stress, the try this process usually uses a transfer setting corresponding to a 9598% complete cavity where the screw changes from a continuous velocity to a constant pressure control.

Once the screw gets to the transfer setting the packaging pressure is applied, which completes mould filling as well as makes up for thermal shrinking, which is quite high for thermoplastics about numerous other materials. The packaging stress is used up until the entrance (tooth cavity entrance) solidifies. As a result of its tiny dimension, the entrance is normally the first area to strengthen via its whole thickness.: 16 Once the gateway solidifies, no more product can get in the dental caries; why not find out more appropriately, the screw reciprocates and gets product for the next cycle while the material within the mould cools down to ensure that it can be expelled as well as be dimensionally stable.